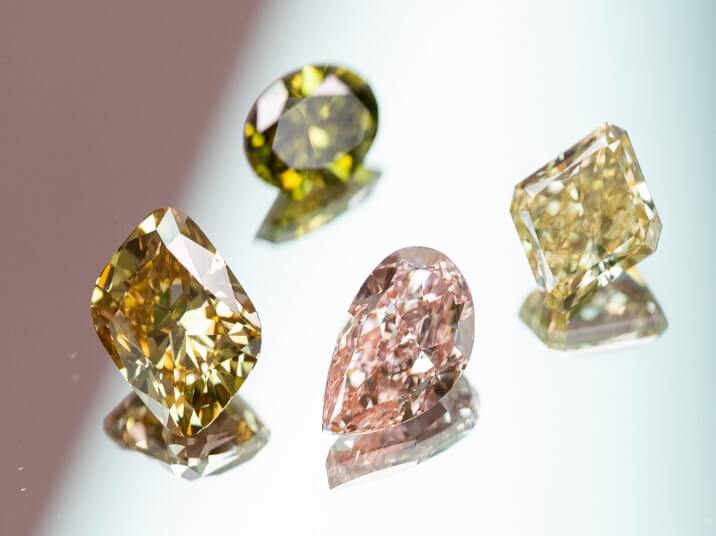

*CVD Color

Additionally, the cvd process can be used to create diamonds of different colors by introducing trace amounts of other elements such as nitrogen or born into the gas mixture.

Yes, lab-grown diamonds are just as real as natural diamonds, the only difference is their origin.

Lab-grown diamonds are formed in a laboratory environment, while natural diamonds are formed deep within the earth. From a chemical, physical, and optical standpoint, lab diamonds are identical to natural diamonds, with the same hardness, brilliance, and fire.

Lab diamonds are graded using the same fourCs—cut,color,clarity, and caratweight —as natural diamonds. Reputable gemological labs, like the Gemological Institute of America (GIA) and the International Gemological Institute (IGI), certify lab-created diamonds according to the same standards as natural ones.

Lab-grown diamonds possess the same chemical and physical properties as natural diamonds, produced through technology that simulates the conditions of natural diamond formation.

Lab grown diamonds cost less than natural diamonds of comparable quality.

From a chemical, physical, and optical standpoint, lab diamonds match natural diamonds in terms of hardness, brilliance, and fire.

The Lab-Grown diamonds have revolutionized the jewelry conditions, offering a more ethical and environmentally friendly option without compromising on quality.

HPHT:In 1954, a team of scientists at General Electric, led by Tracy Hall, successfully created synthetic diamonds using the high pressure, high temperature (HPHT) method. This process simulates natural diamond formation by applying pressures up to 5 GPa and temperatures over 1400 degrees Celsius. A small diamond seed is placed in a press with a carbon source like graphite. As conditions intensify, carbon atoms dissolve and crystallize around the seed, forming a larger diamond. The resulting diamonds are nearly indistinguishable from natural ones in both physical and optical properties.

CVD:The HPHT method was the first successful technique for creating synthetic diamonds, but the chemical vapor deposition (CVD) method has recently gained popularity for producing high-quality diamonds with more control over growth. In CVD, a diamond seed is placed in a vacuum chamber filled with methane, which is heated to about 800 degrees Celsius, breaking down the gas into carbon atoms. These atoms laid onto the seed to form a diamond crystal. CVD allows for precise control over the diamond's size, shape, and purity, enabling the creation of diamonds free from natural inclusions and impurities.

Different production methods produce the same price. Smaller diamonds are effectively produced using HPHT, while CVD offers better control over diamond size.

Additionally, the cvd process can be used to create diamonds of different colors by introducing trace amounts of other elements such as nitrogen or born into the gas mixture.

There's no need to worry much, we'll assist you in selecting the right material based on your design requirements and budget. This information is intended to help you understand the material you're using.